A konferencia tervezett programja

2026. március 26. (csütörtök)

| 9:00 – 10:00 |

Regisztráció

|

| 10:00 - 12:00 |

Megnyitó

Az előadók profiljai és az absztraktok lentebb olvashatók. |

| 12:00 - 13:00 |

Ebédszünet

|

| 13:00 - 15:00 |

Szekció előadások

|

| 18:00 |

Vacsora

|

2026. március 27. (péntek)

| 9:00 - 10:30 |

Szekcióülések

|

| 10:30 - 12:00 |

Vállalati panel

|

| 12:00 - 13:00 |

Ebéd

|

Plenáris előadók

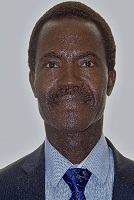

| Dr. (Prof) Andre D.L. Batako - Track Record - Reader in Sustainable Advanced Manufacturing Technologies, The General Engineering Research Institute, Liverpool John Moores University, UK | ||

|---|---|---|

|

TITLE: SUSTAINABLE MANUFACTURING, ETHNICS & CHALLENGES FOR A TRUE CIRCULAR ECONOMY The transition to a circular economy represents one of the most transformative ambitions of the 21st century, demanding not only technological innovation but also deep ethical reflection form the inception throughout the life of the innovation. Sustainable manufacturing lies at the heart of this transition, where material cycles are closed, waste becomes a resource, and value creation aligns with ecological and social well-being. Yet, realizing a true circular economy remains fraught with ethical dilemmas and systemic challenges. Here, we explore the moral, technological, and policy dimensions of sustainable manufacturing within a circular economy framework. We interrogate questions of equity, transparency, and responsibility across global value chains, asking who benefits, who bears the costs, and how circularity can avoid reproducing existing inequalities e.g. child labour, unfair prices and wages. Equally, we examine the challenges of implementing circular principles at scale, from lifecycle design and supply chain traceability, materials, to energy use, data ethics, and regulatory coherence. Drawing on contemporary research, industry practices, and international policy frameworks such as the SDGs and the EU Green Deal, the presentation emphasizes the need for ethical governance, interdisciplinary collaboration, and innovation ecosystems that promote long term sustainability over short term gains. Ultimately, this is a call for a rethinking of manufacturing ethics, where circularity is not merely a technical fix, but a moral commitment to justice, stewardship, and resilience in the current geo-political era, in which human activity has the most detrimental influence on climate and natural habitat. Anthropocene. Greg Ramm, Country Director for Save the Children said: “We’re seeing a huge need for green energy solutions globally, which heavily relies on cobalt – but it is imperative that what fuels our smartphones, computers, and electric cars doesn’t also fuel child rights violations” |

|

| Prof. Katarzyna Antosz Department of Manufacturing Processes and Production Engineering, Rzeszow University of Technology, Rzeszów, Poland | ||

|---|---|---|

|

Reader in Sustainable Advanced Manufacturing Technologies, The General Engineering Research Institute, Liverpool John Moores University, UK TITLE: PREDICT, IMPROVE AND SUSTAIN: LEAN SIX SIGMA POWERED BY MACHINE LEARNING As global industrial processes become increasingly complex and variable, integrating machine learning (ML) with Lean Six Sigma allows for faster, more reliable, evidence-based improvements. This presentation will demonstrate how ML can accelerate Lean Six Sigma projects by streamlining the 'Measure' and 'Analyse' phases through structured data preparation, feature engineering and predictive modelling. It will also show how Lean goals such as improved flow and waste reduction can be achieved in the 'Improve' phase. Furthermore, it will demonstrate how gains can be sustained in the Control phase by operationalising models with MLOps practices, including model validation, deployment governance, and continuous monitoring of data and model drift. The DMAIC cycle will form the basis of the integration, with ML monitoring being linked to Statistical Process Control (SPC) to close the loop. Selected industrial case studies will be discussed to illustrate scalable implementation paths and typical pitfalls in high-variability production environments. The key message is that ML strengthens decision-making in Six Sigma projects and increases the probability of achieving a sustainable, repeatable impact on a large scale. |

|